-

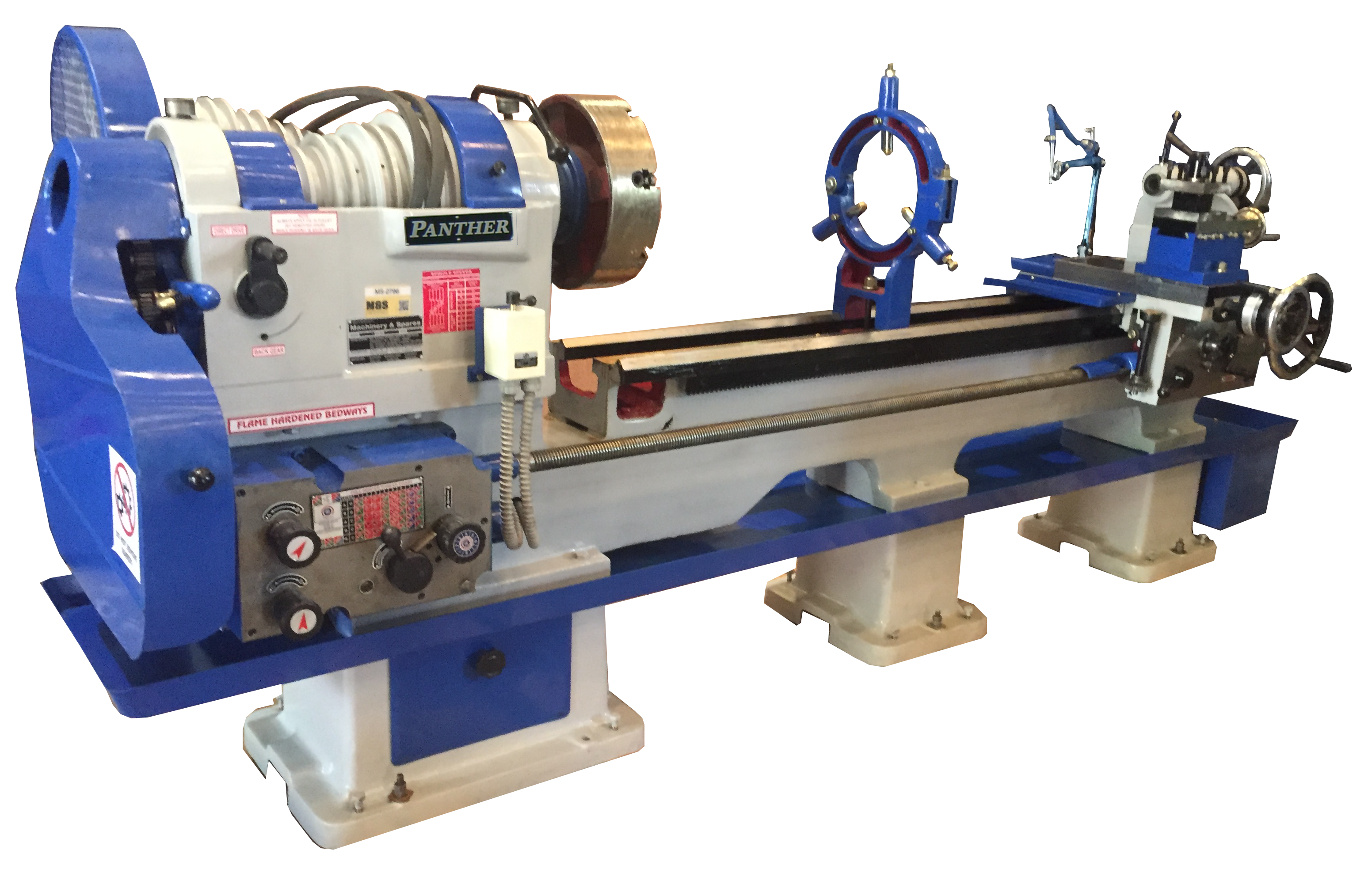

1050 SeriesPANTHER GEARED PRECISION LATHES

1050 SeriesPANTHER GEARED PRECISION LATHES

-

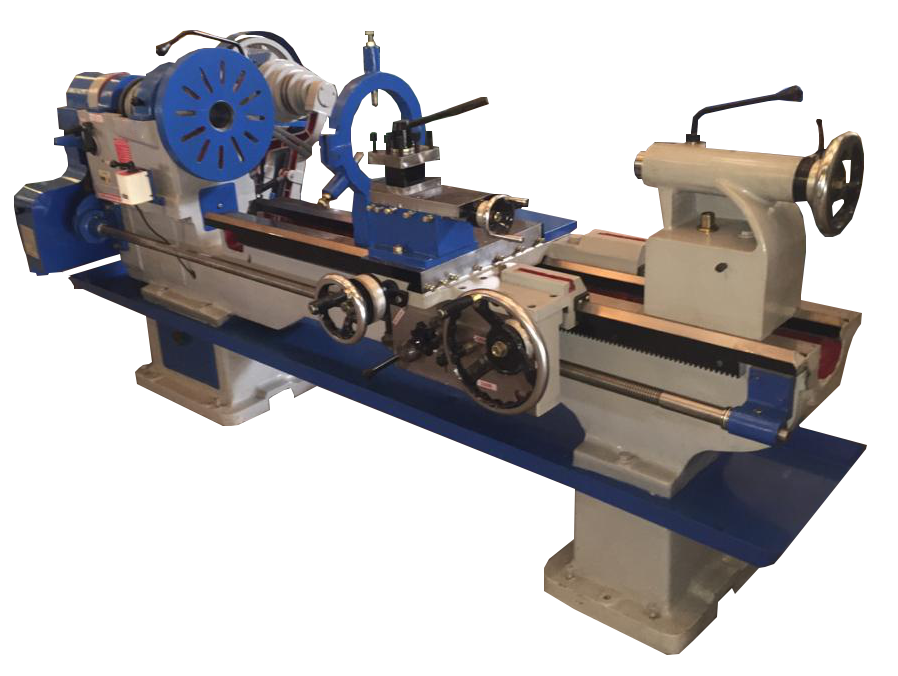

1350 / 1650 SeriesPANTHER ALL GEARED PRECISION

1350 / 1650 SeriesPANTHER ALL GEARED PRECISION

-

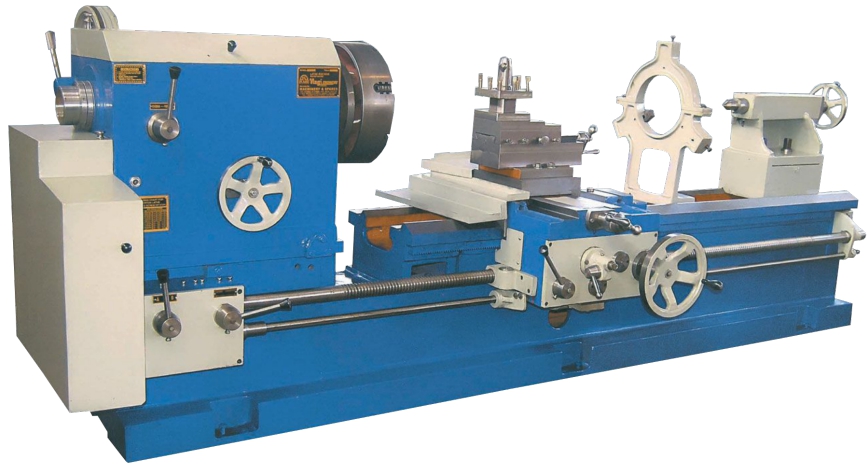

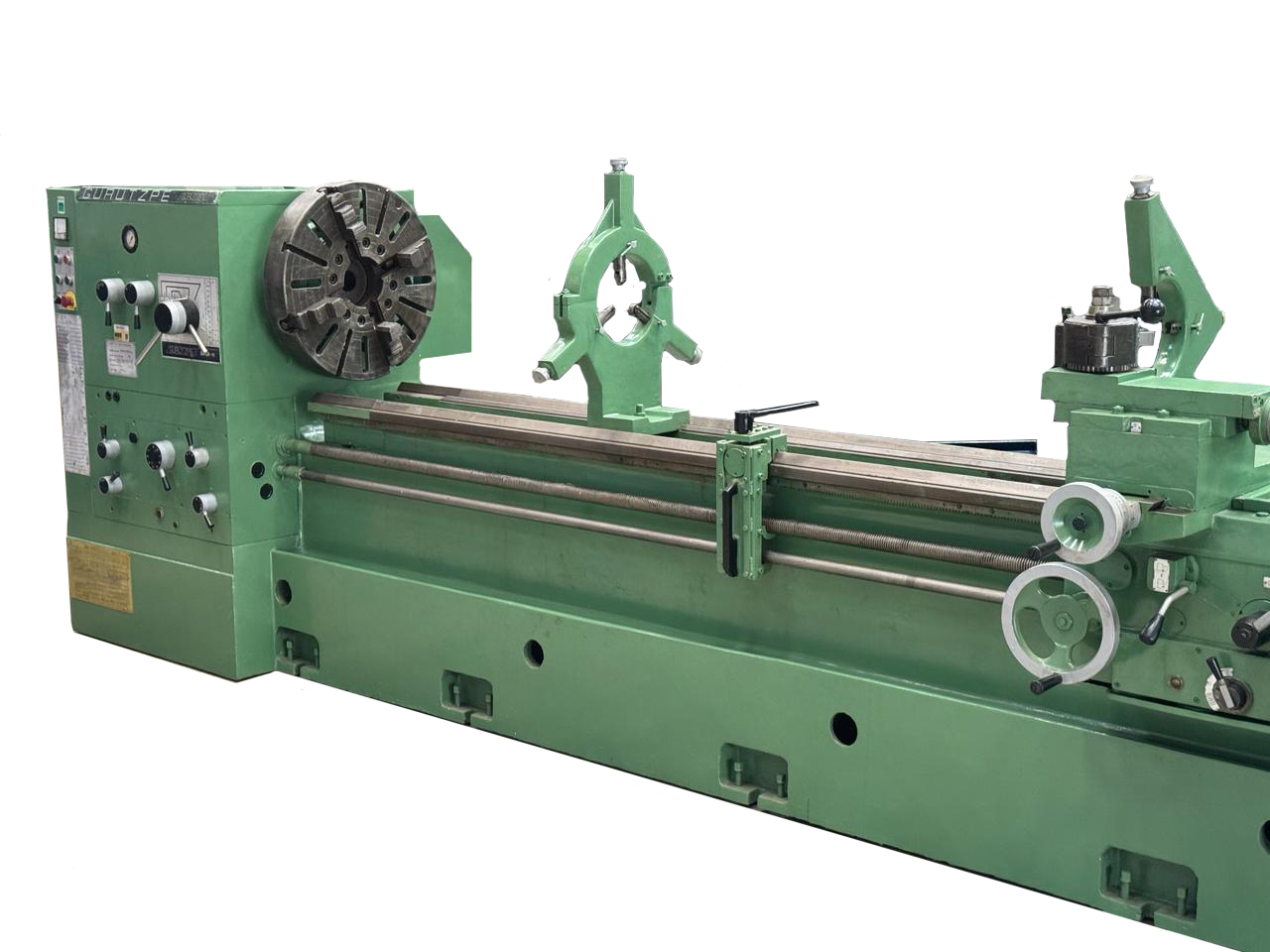

2050 SERIESPANTHER ALL GEARED HEAVY DUTY LATHES

2050 SERIESPANTHER ALL GEARED HEAVY DUTY LATHES

-

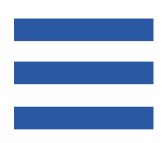

3050 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHE

3050 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHE

-

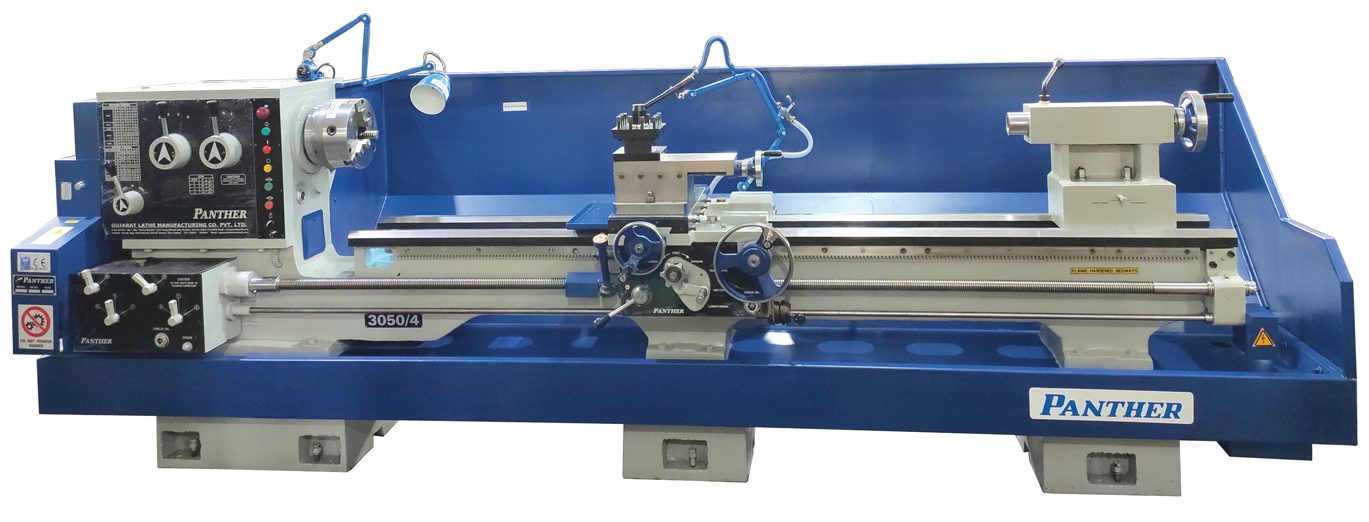

4080 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHES

4080 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHES

-

4610,5610 & 6610 SeriesPANTHER EXTRA HEAVY DUTY LATHE

4610,5610 & 6610 SeriesPANTHER EXTRA HEAVY DUTY LATHE

-

PFL SeriesPANTHER FACING LATHE

PFL SeriesPANTHER FACING LATHE

-

PFC SeriesPANTHER HEAVY DUTY CNC LATHES

PFC SeriesPANTHER HEAVY DUTY CNC LATHES

-

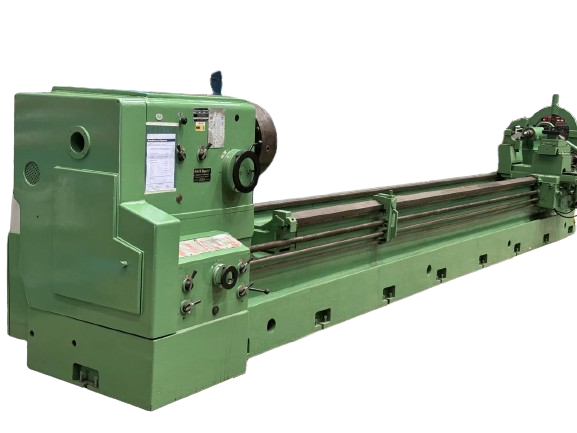

Panther Lathe GLHPANTHER LATHE GLH

Panther Lathe GLHPANTHER LATHE GLH

-

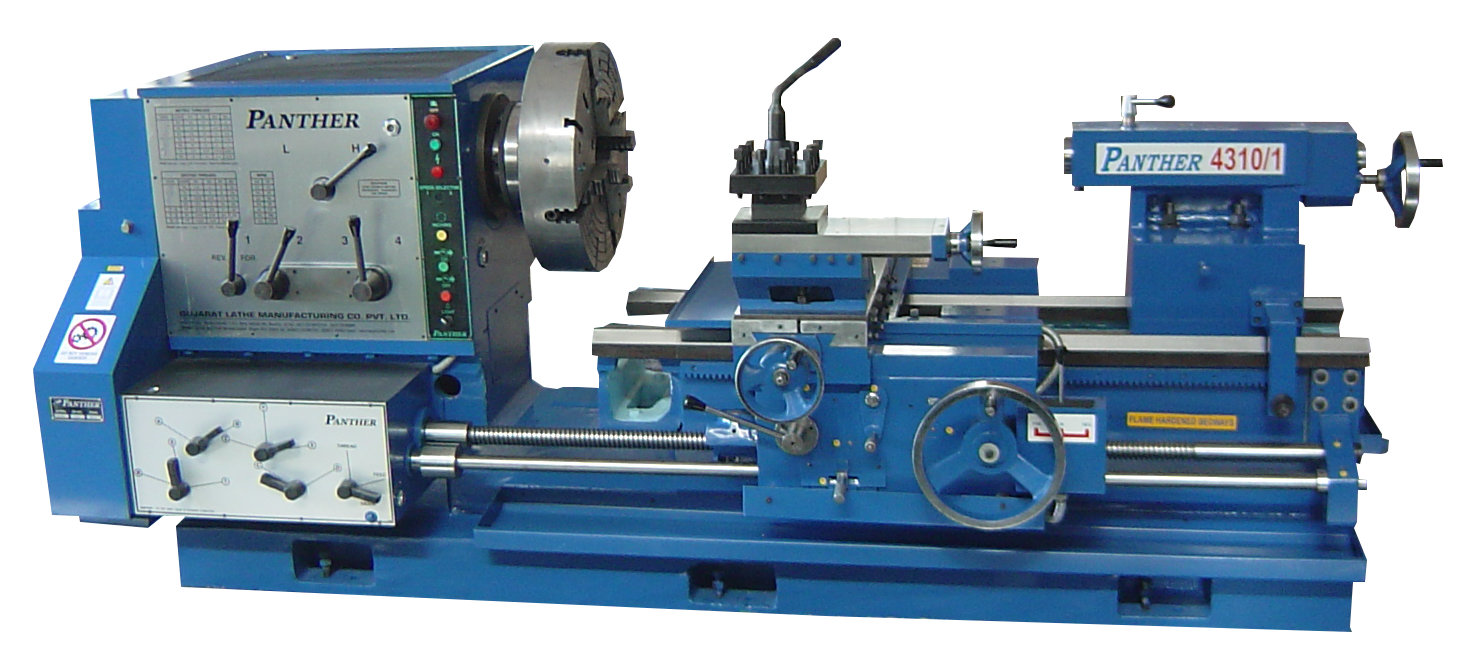

Panther GLH & GLEH SeriesHEAVY DUTY PRECISION LATHE MACHINE WITH FLAME HARDENED GUIDEWAYS

Panther GLH & GLEH SeriesHEAVY DUTY PRECISION LATHE MACHINE WITH FLAME HARDENED GUIDEWAYS

-

PL & PM SeriesPECO LIGHT DUTY & MEDIUM DUTY

PL & PM SeriesPECO LIGHT DUTY & MEDIUM DUTY

-

Peco PLP SeriesHEAVY DUTY CONE PULLEY TYPE PRECISION

Peco PLP SeriesHEAVY DUTY CONE PULLEY TYPE PRECISION

-

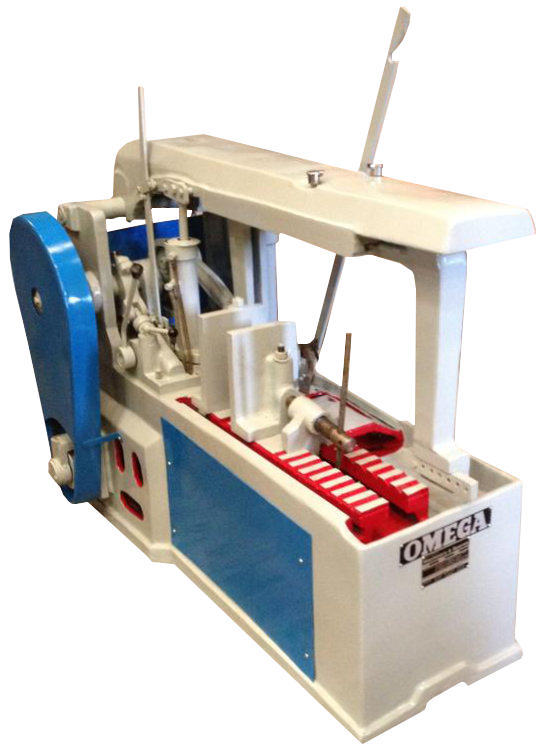

OMEGA N SeriesHEAVY DUTY ‘V’ BELT DRIVEN

OMEGA N SeriesHEAVY DUTY ‘V’ BELT DRIVEN

-

YSD HGS SeriesHYDRAULIC/NC/CNC GUILLOTINE SHEARING

YSD HGS SeriesHYDRAULIC/NC/CNC GUILLOTINE SHEARING

-

Samson SSB seriesHYDRAULIC SHEARING WITH MOTORISED BACK GAUGE

Samson SSB seriesHYDRAULIC SHEARING WITH MOTORISED BACK GAUGE

-

YSD HGO SeriesHYDRAULIC /NC /CNC GUILLOTINE SHEARING

YSD HGO SeriesHYDRAULIC /NC /CNC GUILLOTINE SHEARING

-

YSD HGN SeriesHYDRAULIC/ NC/CNC GUILLOTINE SHEARING

YSD HGN SeriesHYDRAULIC/ NC/CNC GUILLOTINE SHEARING

-

YSD HGOYSD HYDRAULIC SHEARING MACHINES

YSD HGOYSD HYDRAULIC SHEARING MACHINES

-

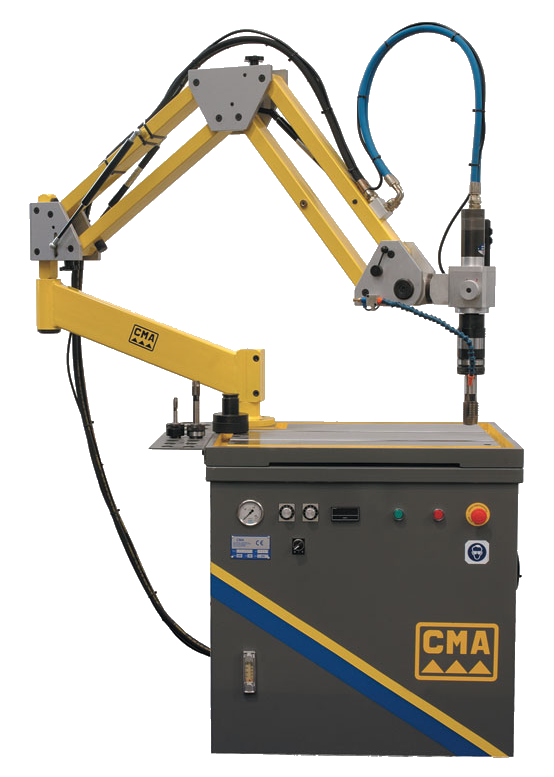

RH,RHM & RHRM SeriesCMA HYDRAULIC TAPPING

RH,RHM & RHRM SeriesCMA HYDRAULIC TAPPING

-

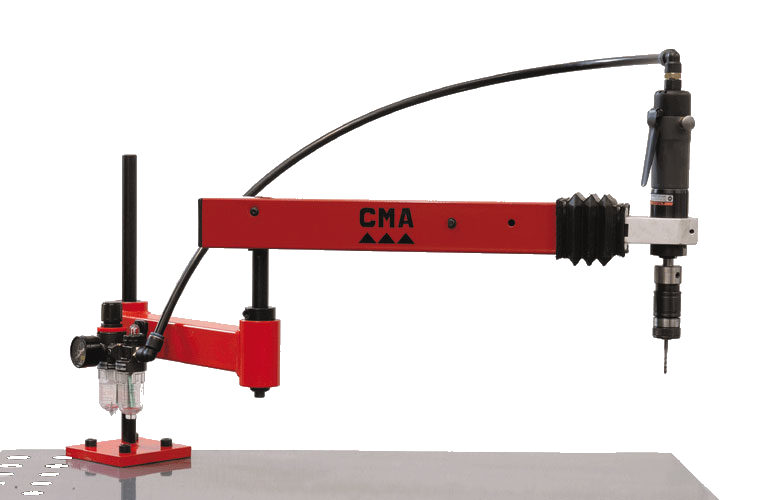

RS SeriesPneumatic Tapping

RS SeriesPneumatic Tapping

-

RN Series TappingPneumatic Tapping - RN Series

RN Series TappingPneumatic Tapping - RN Series

-

RER SeriesElectronic

RER SeriesElectronic

-

RH SeriesHydraulic

RH SeriesHydraulic

-

GH,GHR,GHRM SeriesCMA HYDRAULIC TAPPINGS

GH,GHR,GHRM SeriesCMA HYDRAULIC TAPPINGS

-

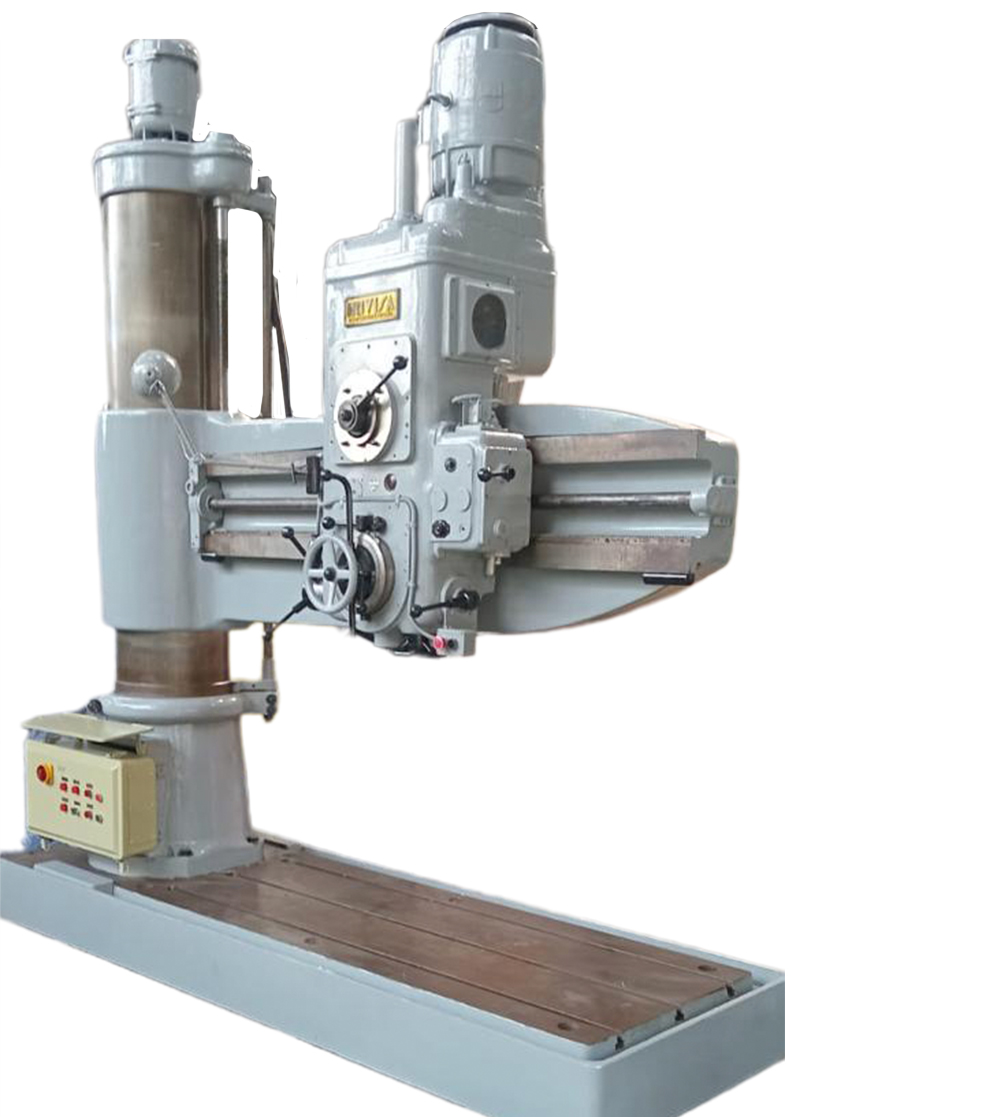

RD SeriesSamson RADIAL DRILLING

RD SeriesSamson RADIAL DRILLING

-

Siddhapura SIC SeriesSYNDICATE RADIAL DRILLING MACHINE

Siddhapura SIC SeriesSYNDICATE RADIAL DRILLING MACHINE

-

Siddhapura Sahyog SER SeriesSIDDHAPURA UNIVERSAL RADIAL DRILLING

Siddhapura Sahyog SER SeriesSIDDHAPURA UNIVERSAL RADIAL DRILLING

-

Siddhapura SE SeriesSIDDHAPURA Pillar Drill Machine

Siddhapura SE SeriesSIDDHAPURA Pillar Drill Machine

-

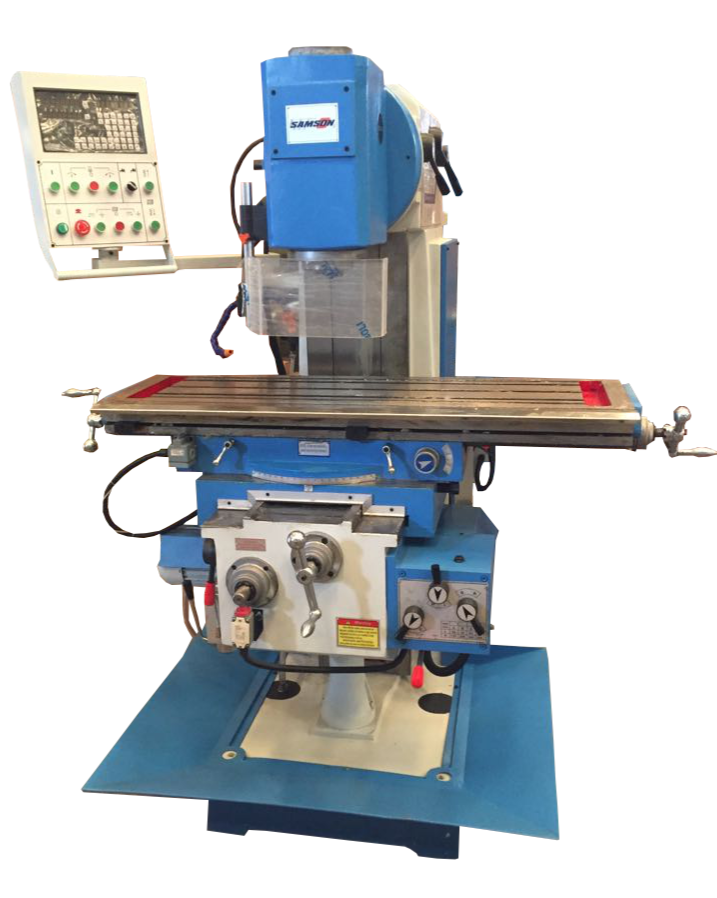

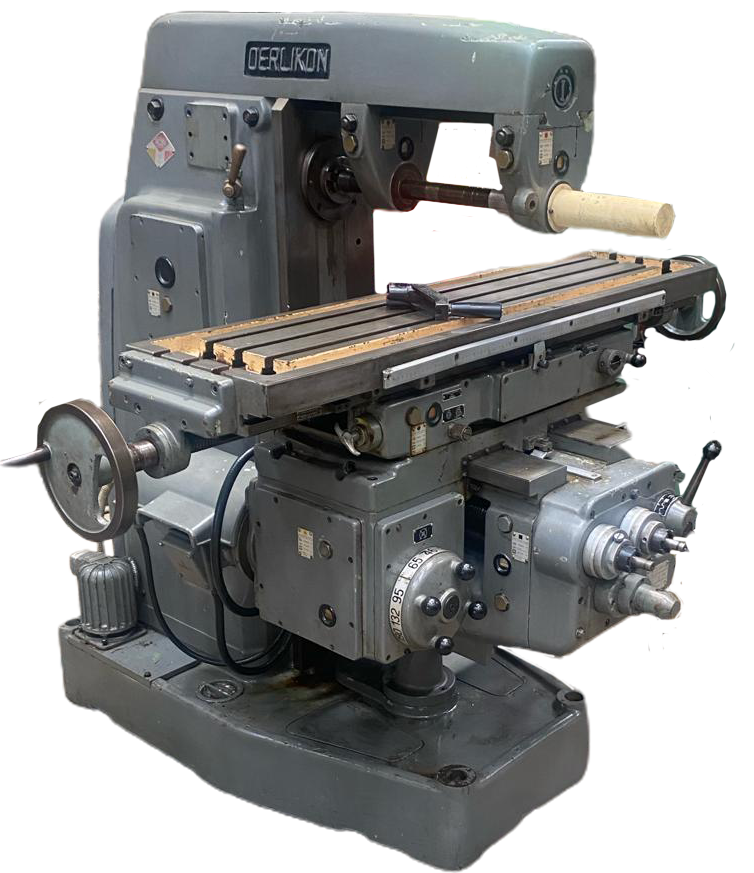

UFM SeriesSAMSON UNIVERSAL MILLING

UFM SeriesSAMSON UNIVERSAL MILLING

-

Samson VFM SeriesVertical Milling Machines

Samson VFM SeriesVertical Milling Machines

-

Samson 4KS SeriesRAM TURRET MILLING

Samson 4KS SeriesRAM TURRET MILLING

-

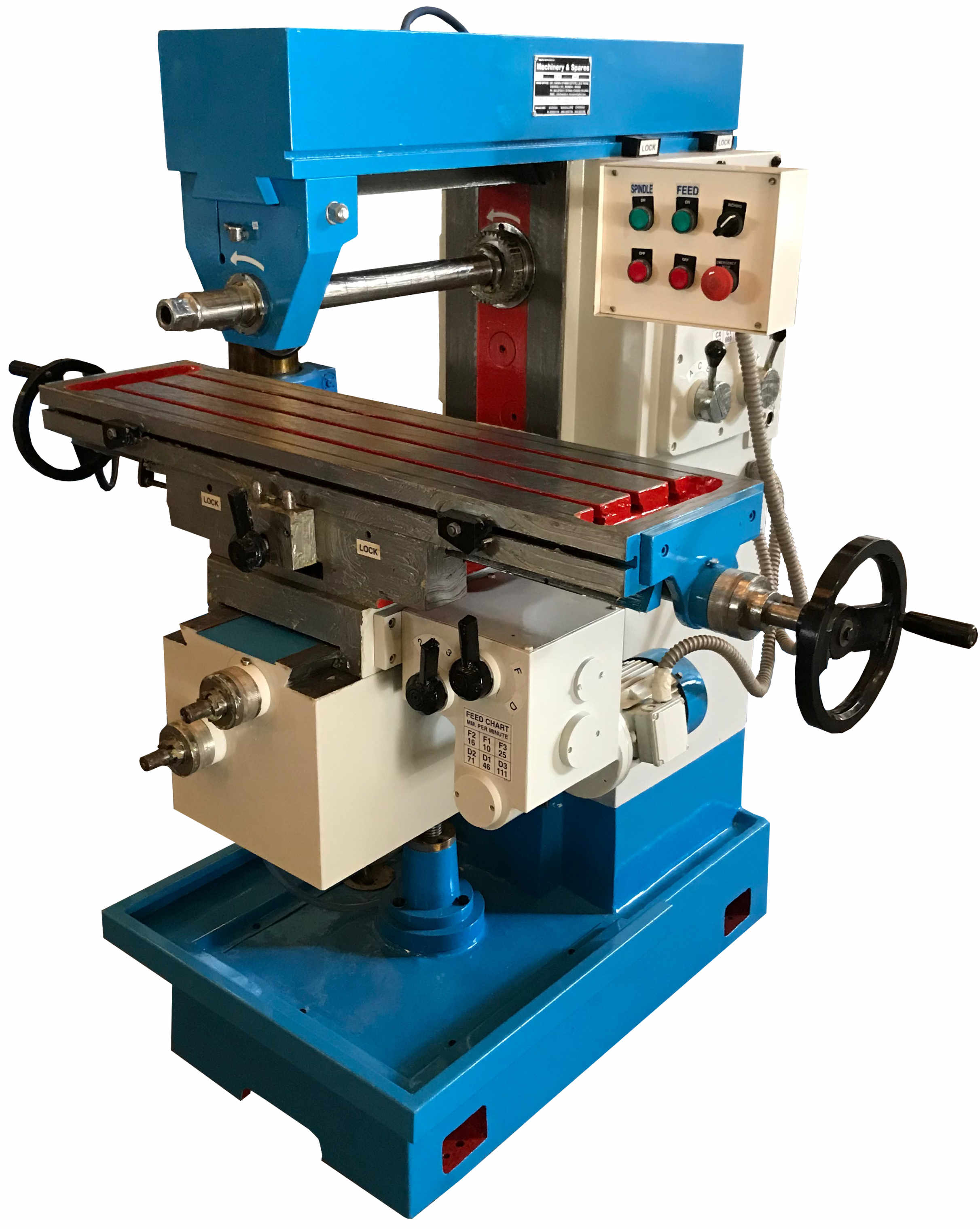

Peco Universal Milling P-2UPECO P-2U UNIVERSAL MILLING MACHINE

Peco Universal Milling P-2UPECO P-2U UNIVERSAL MILLING MACHINE

-

VFM SERIESSAMSON VERTICAL MILLING MACHINE

VFM SERIESSAMSON VERTICAL MILLING MACHINE

-

UFS SeriesSAMSON UNIVERSAL SWIVEL HEAD MILLING MACHINE

UFS SeriesSAMSON UNIVERSAL SWIVEL HEAD MILLING MACHINE

-

Samson VHF1 SeriesKNEE TYPE MILLING

Samson VHF1 SeriesKNEE TYPE MILLING

-

Samson VHF2/VHF2A SeriesDRILLING CUM MILLING WITH X AXIS AUTOMATIC DRO

Samson VHF2/VHF2A SeriesDRILLING CUM MILLING WITH X AXIS AUTOMATIC DRO

-

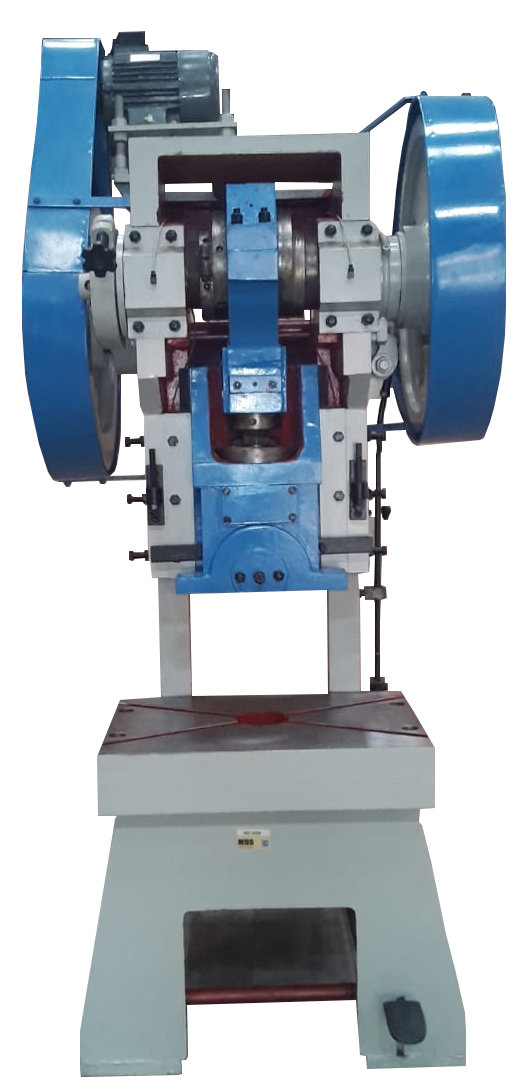

SNX-2 SeriesSEW DOUBLE CRANK CROSS SHAFT

SNX-2 SeriesSEW DOUBLE CRANK CROSS SHAFT

-

SNX SeriesSEW EXTRA RIGID CROSS SHAFT POWER PRESS

SNX SeriesSEW EXTRA RIGID CROSS SHAFT POWER PRESS

-

SNXR SeriesSTRAIGHT SIDED SINGLE CRANK

SNXR SeriesSTRAIGHT SIDED SINGLE CRANK

-

HMX SeriesLINK MOTION PROGRESSIVE DIE

HMX SeriesLINK MOTION PROGRESSIVE DIE

-

SBP SeriesHEAVY STAMPING STRAIGHT SIDED

SBP SeriesHEAVY STAMPING STRAIGHT SIDED

-

SXP-2 SeriesStraight Sided Double Crank

SXP-2 SeriesStraight Sided Double Crank

-

SNK SeriesHEAVY DUTY GAP FRAME

SNK SeriesHEAVY DUTY GAP FRAME

-

SCL SeriesSTRAIGHT SIDED CRANKLESS

SCL SeriesSTRAIGHT SIDED CRANKLESS

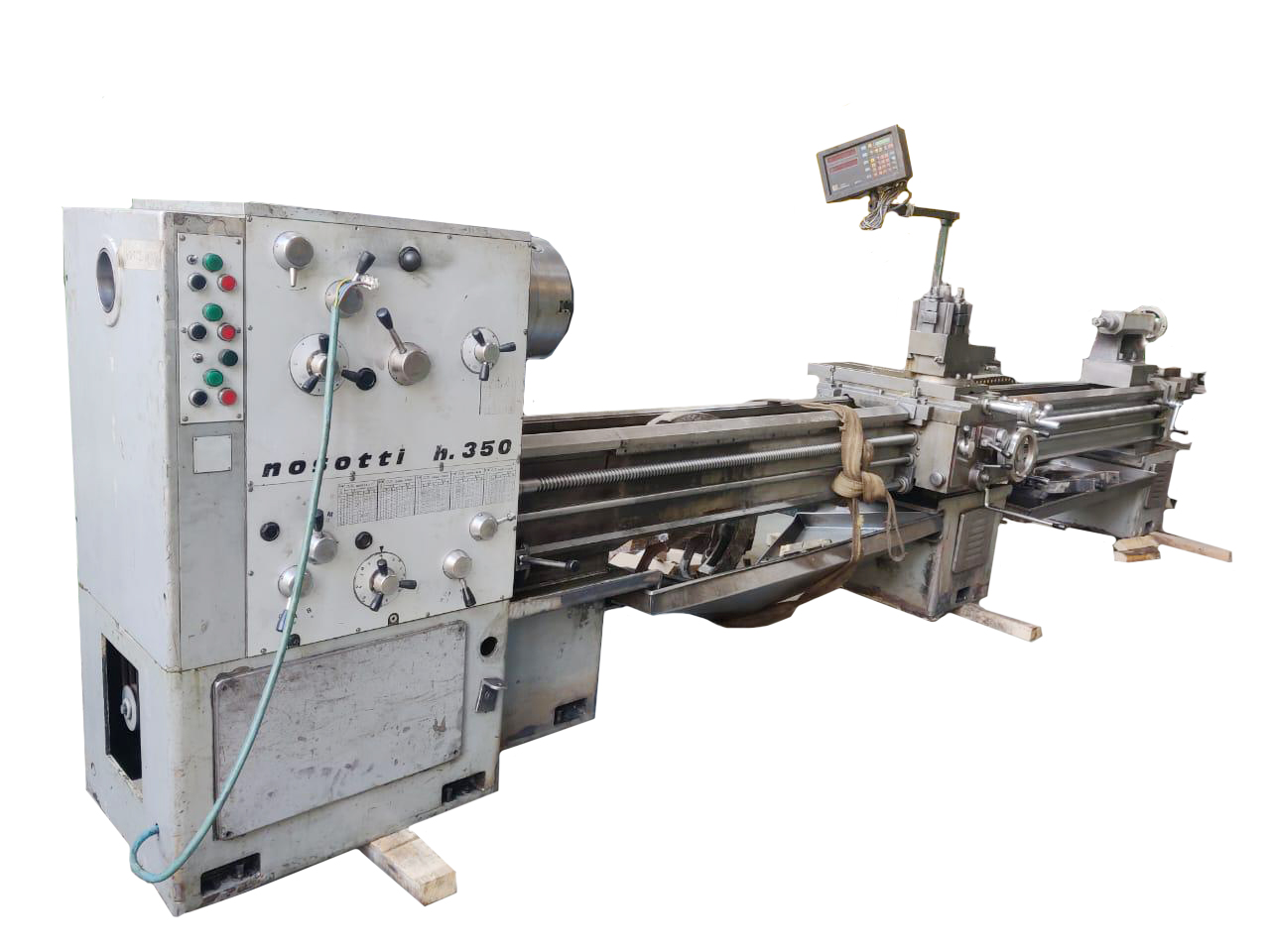

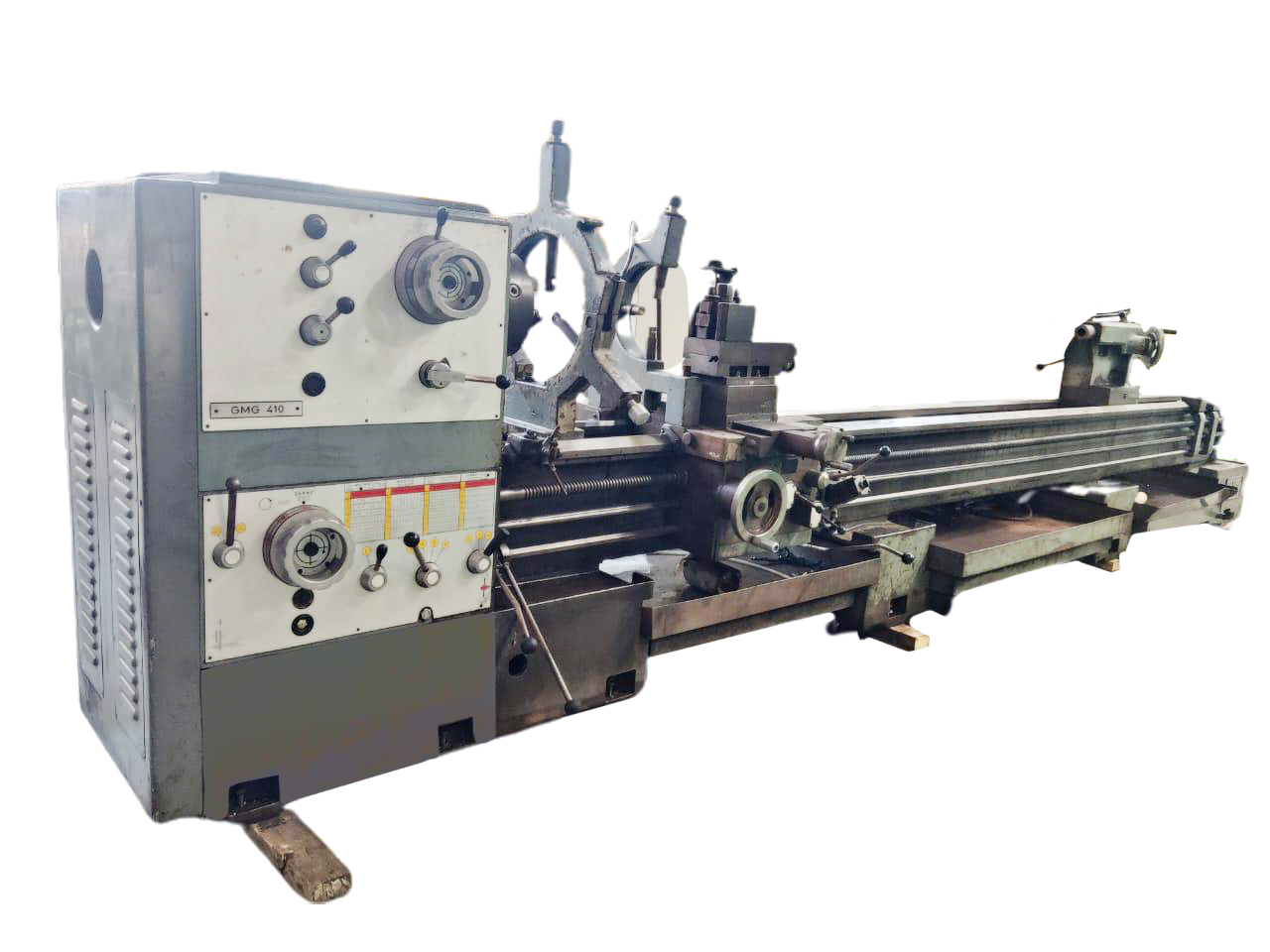

Lathe Machines

ALL GEARED LATHE MACHINES

Belt Driven Lathe Machines ( Cone Pulley Lathes )

vertical turret lathe

Hydraulic Press Brakes & Shearing Machines

Hydraulic Shearing ( Variable Rake Angle ) Machines

Hydraulic Press Brake

Tapping Machines

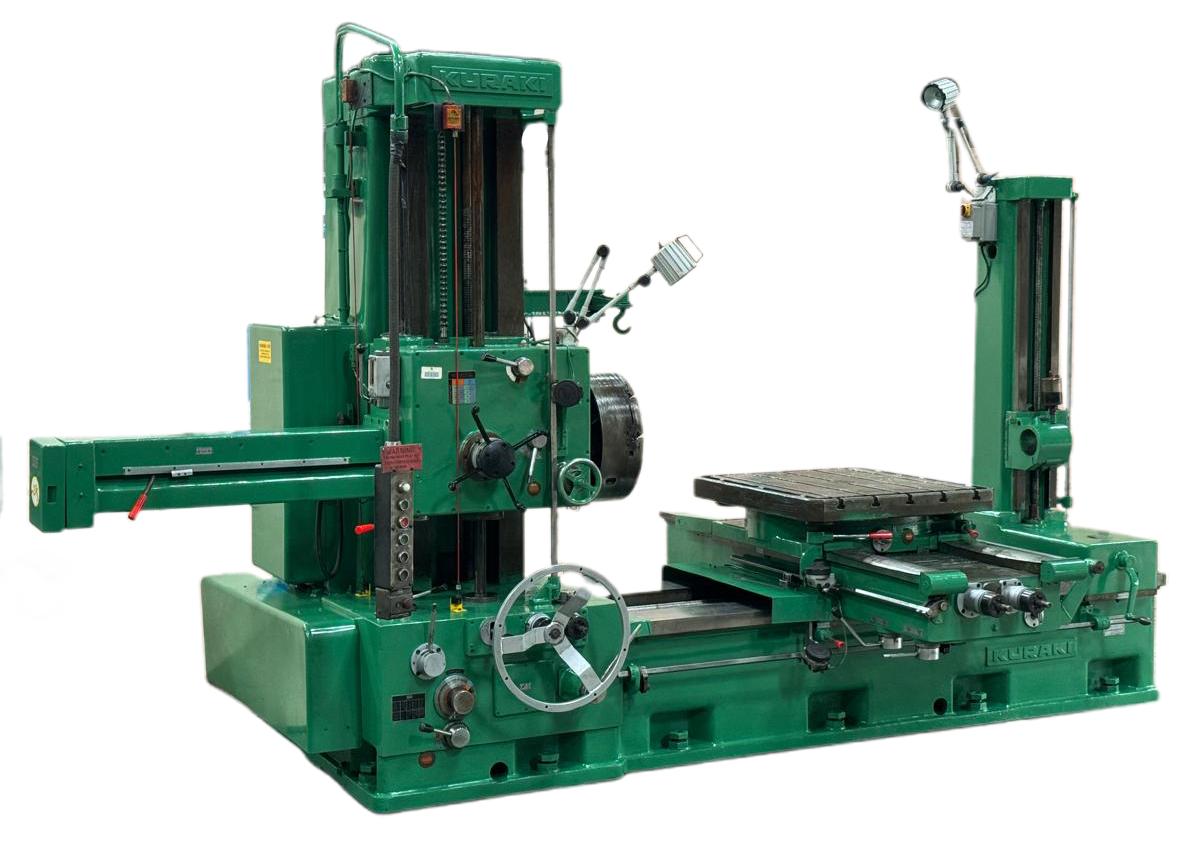

Radial Drilling Machines

Milling Machines

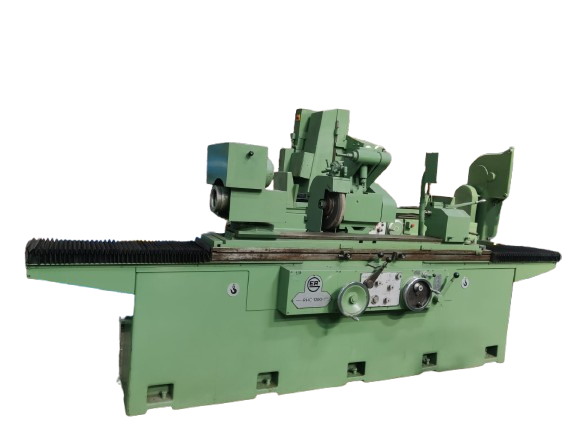

Surface Grinders

Milling Cum Drilling Machines

Mechnical Shearing Machines ( Guillotine Shears )

Mechanical Shearing Machine

Power Press

Pneumatic Clutch Power Press

Rolling Key Clutch Power Press

Plate Bending Machines

Shaping Machine

Cutting Machine

-

1050 SeriesPANTHER GEARED PRECISION LATHES

1050 SeriesPANTHER GEARED PRECISION LATHES

-

1350 / 1650 SeriesPANTHER ALL GEARED PRECISION

1350 / 1650 SeriesPANTHER ALL GEARED PRECISION

-

2050 SERIESPANTHER ALL GEARED HEAVY DUTY LATHES

2050 SERIESPANTHER ALL GEARED HEAVY DUTY LATHES

-

3050 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHE

3050 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHE

-

4080 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHES

4080 SeriesPANTHER ALL GEARED HEAVY DUTY PRECISION LATHES

-

4610,5610 & 6610 SeriesPANTHER EXTRA HEAVY DUTY LATHE

4610,5610 & 6610 SeriesPANTHER EXTRA HEAVY DUTY LATHE

-

PFL SeriesPANTHER FACING LATHE

PFL SeriesPANTHER FACING LATHE

-

PFC SeriesPANTHER HEAVY DUTY CNC LATHES

PFC SeriesPANTHER HEAVY DUTY CNC LATHES

-

Panther Lathe GLHPANTHER LATHE GLH

Panther Lathe GLHPANTHER LATHE GLH

-

Panther GLH & GLEH SeriesHEAVY DUTY PRECISION LATHE MACHINE WITH FLAME HARDENED GUIDEWAYS

Panther GLH & GLEH SeriesHEAVY DUTY PRECISION LATHE MACHINE WITH FLAME HARDENED GUIDEWAYS

-

PL & PM SeriesPECO LIGHT DUTY & MEDIUM DUTY

PL & PM SeriesPECO LIGHT DUTY & MEDIUM DUTY

-

Peco PLP SeriesHEAVY DUTY CONE PULLEY TYPE PRECISION

Peco PLP SeriesHEAVY DUTY CONE PULLEY TYPE PRECISION

-

OMEGA N SeriesHEAVY DUTY ‘V’ BELT DRIVEN

OMEGA N SeriesHEAVY DUTY ‘V’ BELT DRIVEN

ALL GEARED LATHE MACHINES

Belt Driven Lathe Machines ( Cone Pulley Lathes )

vertical turret lathe

-

YSD HGS SeriesHYDRAULIC/NC/CNC GUILLOTINE SHEARING

YSD HGS SeriesHYDRAULIC/NC/CNC GUILLOTINE SHEARING

-

Samson SSB seriesHYDRAULIC SHEARING WITH MOTORISED BACK GAUGE

Samson SSB seriesHYDRAULIC SHEARING WITH MOTORISED BACK GAUGE

-

YSD HGO SeriesHYDRAULIC /NC /CNC GUILLOTINE SHEARING

YSD HGO SeriesHYDRAULIC /NC /CNC GUILLOTINE SHEARING

-

YSD HGN SeriesHYDRAULIC/ NC/CNC GUILLOTINE SHEARING

YSD HGN SeriesHYDRAULIC/ NC/CNC GUILLOTINE SHEARING

-

YSD HGOYSD HYDRAULIC SHEARING MACHINES

YSD HGOYSD HYDRAULIC SHEARING MACHINES

Hydraulic Shearing ( Variable Rake Angle ) Machines

Hydraulic Press Brake

Mechanical Shearing Machine

-

SNX-2 SeriesSEW DOUBLE CRANK CROSS SHAFT

SNX-2 SeriesSEW DOUBLE CRANK CROSS SHAFT

-

SNX SeriesSEW EXTRA RIGID CROSS SHAFT POWER PRESS

SNX SeriesSEW EXTRA RIGID CROSS SHAFT POWER PRESS

-

SNXR SeriesSTRAIGHT SIDED SINGLE CRANK

SNXR SeriesSTRAIGHT SIDED SINGLE CRANK

-

HMX SeriesLINK MOTION PROGRESSIVE DIE

HMX SeriesLINK MOTION PROGRESSIVE DIE

-

SBP SeriesHEAVY STAMPING STRAIGHT SIDED

SBP SeriesHEAVY STAMPING STRAIGHT SIDED

-

SXP-2 SeriesStraight Sided Double Crank

SXP-2 SeriesStraight Sided Double Crank

-

SNK SeriesHEAVY DUTY GAP FRAME

SNK SeriesHEAVY DUTY GAP FRAME

-

SCL SeriesSTRAIGHT SIDED CRANKLESS

SCL SeriesSTRAIGHT SIDED CRANKLESS